IML In Mould Labelling process

In Mould Labelling or with the help of static electricity, static placement(static gluing) is the standard in the injection moulding IML industry, thermoforming IML and also the blow moulding IML industry. Instead of conventional methods like decorating end products by printing directly or placing an adhesive label onto the product, the decoration is achieved with a pre-printed plastic polypropylene (PP) label. The pre printed PP label is inserted in the mold and then the molten PP is added to the mould. The label then fuses and the product takes the shape of the mould.

Benefits from using (static) IML label application

- eliminates screen printing, label application or pad printing on product

- no corona or flame treaters needed to prepare the surface

- higher quality graphics

- rapid changing of graphics possible

- recyclable with label material same as moulded product

- hygienic much better result for the content

- less storage space, press to final packaging

- single step production method for cups and buckets

- less handling, less costs, less storage etc.

The in mold labeling(IML) process

How does IML work? In the injection moulding process a pre-printed IML-label is picked up and placed in the mould cavity where it sticks, exactly on the wished position, due to the electrostatic charging. After closing the mould cavities the label will be moulded together with the end-product and comes out as a finished, fully recyclable product. To realise a high reliable, competitive IML-project the choice of an IML-suitable label is of decisive significance. Whether you are an end-user or a robotics manufacturer, Simco can assist you with advice and knowledge in creating the perfect IML solution. Big advantage of the Electrostatic In Mould Labelling IML-process is that the moulds are much easier to build so cheaper to produce compared to the old vacuum technique. Since no vacuum channels through the mold is needed the production process is not interrupted by cleaning these contaminated channels, resulting in high-output, competitive IML production process.

IML Static - Charging Technology for label placement

There are three different Charging Methods for In Mold labelling(click to find out more):

- Electrostatic Pinning: Charging the label inside the mould by High Voltage Generators

- High speed Direct IML Charging: Charging the label inside the mould by a semi-conductive material(Patented by Simco)

- Simplified IML for metallic labels: Charging the label outside the mould and transfer charged label inside the mould

Typical IML Application

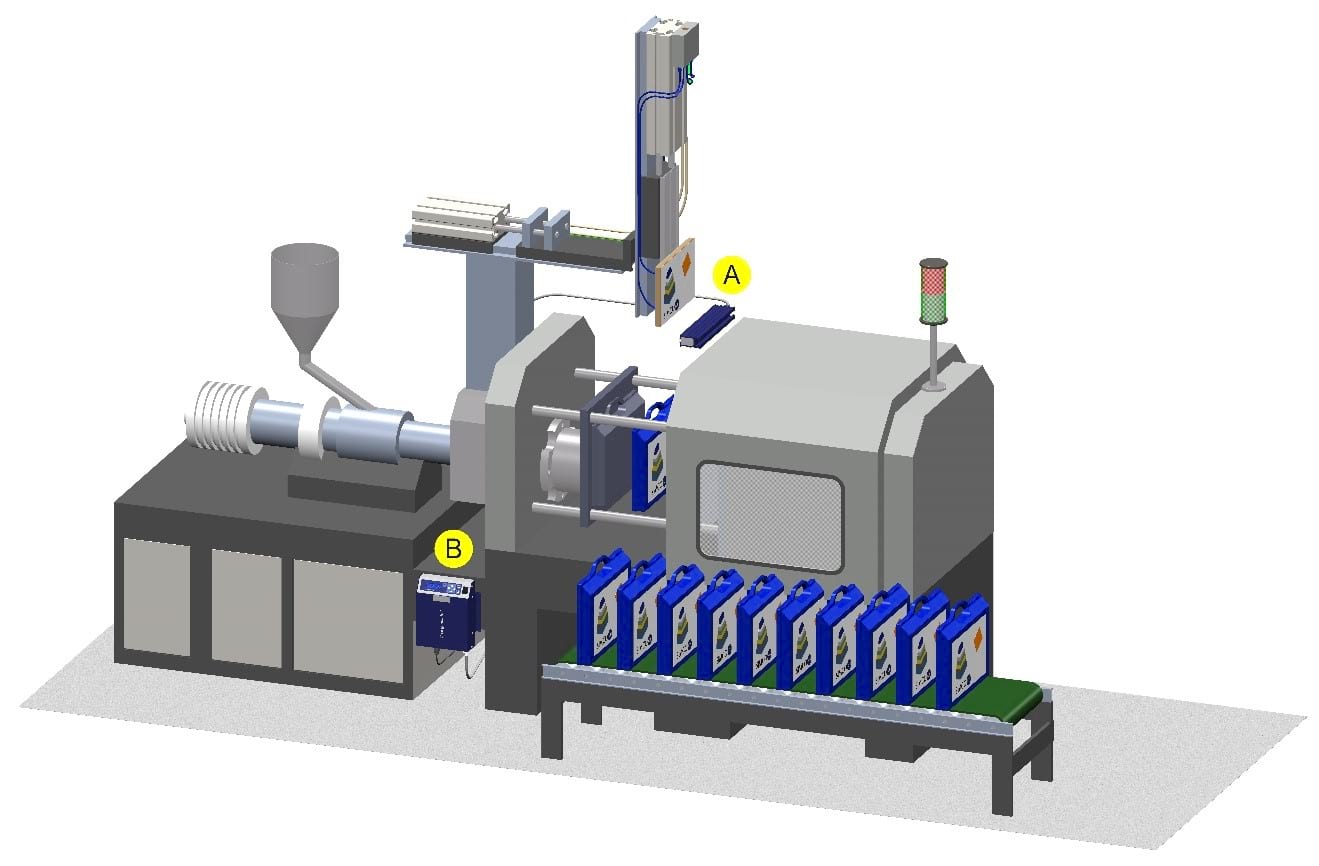

Schematic overvieuw of IML application, label placement by means of static electricity

IML, In Mould Labelling, is indispensable in the production of injection moulded products

A perfect example is packaging of food products and many plastic products for domestic use. Many products are produced with the aid of a static charge. Instead of printing directly or placing a sticky label onto the product, the print is achieved with a pre-printed plastic label. The pre-printed label is positioned into the injection mould and kept in place by a static charge. This way the label will be moulded together with the product shape and come out as a finished product.

How does IML works?

IML is a process step in the injection moulding process. By a robot, a label is picked up and placed in the mould cavity where it sticks due to the electrostatic charging. After the closing of the mould cavity, the product can be moulded whereby the label is fused with the end product.

What is necessary for applying IML?

- A suitable printed label

- A core with IML electrodes

- A charging generator

- A robot or handling

IML electrodes

Depending on the geometry of the product and the desired cycle time, there are various methods with associated electrodes to apply.

Construction

- Emitter pins in the core, for example IML spider

- Constructed core with IML foam

- Constructed core with IML Easycore

- Constructed core with IML foam simplified with external charging electrode

- Constructed core with IML Easycore simplified with external charging electrode

How can Simco-Ion help you?

Simco-Ion has years of experience with the IML process and has therefore developed special charging generators, IML electrodes and IML electrode materials and charging techniques. A wide range of innovative products can help you to optimise the IML process. Simco-Ion or a local representative can assist you with advice and knowledge to realise your project. For more contact data, go to: www.simco-ion.co.uk/contact