IQ Easy system improves process

![]() -

30. octubre 2016

-

Applications

-

30. octubre 2016

-

Applications

IQ Easy system improves the process at Clondalkin

Clondalkin achieves its objective – by deploying a Simco-Ion IQ Easy – an intelligent system for neutralising static charges!

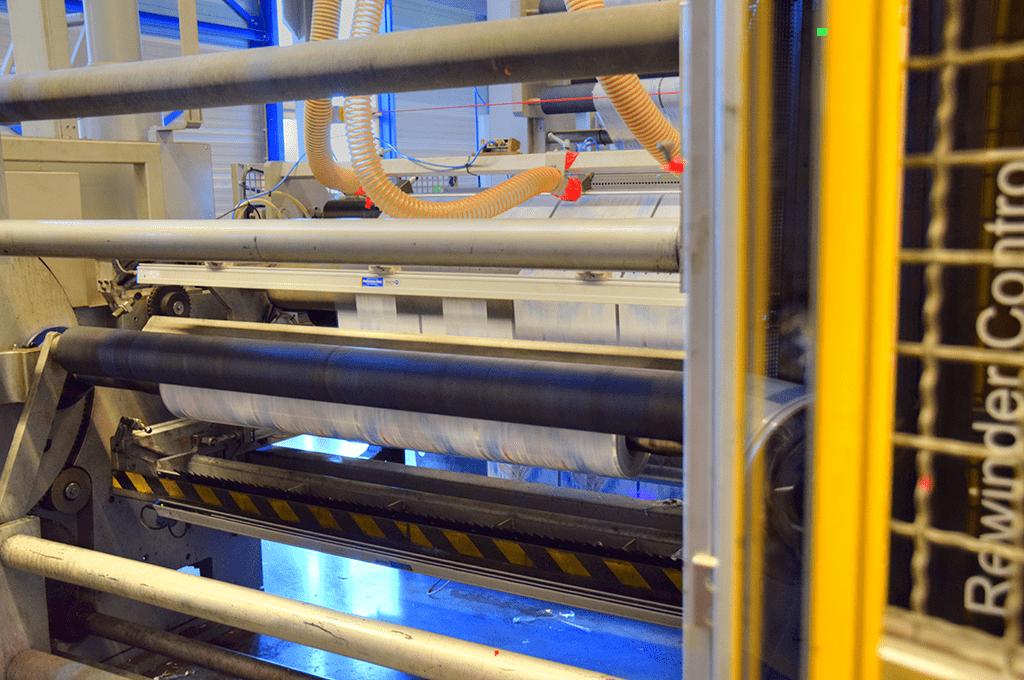

Static charge is a well-known phenomenon occurring in different stages within the production of flexible packaging materials. Especially when it comes to cover foil, it is of vital importance that a roll of printed foil is delivered with the minimum of static charge, if the static charge is too high it will cause problems when the foil is further processed in the end clients packaging machine.

In most cases in the past, the ionisation equipment used for controlling static charges could handle the task. However, the results were always variable, with permissible limits often being exceeded. This was due to the influence of a variety of factors – mainly humidity, foil properties, corona treatment, printing, processing speed and the condition of the neutralising equipment (fouling).

Following extensive testing of the latest Simco-Ion IQ-Easy components deployed at strategic positions within the Comexi flexography machine, the desired results were obtained.

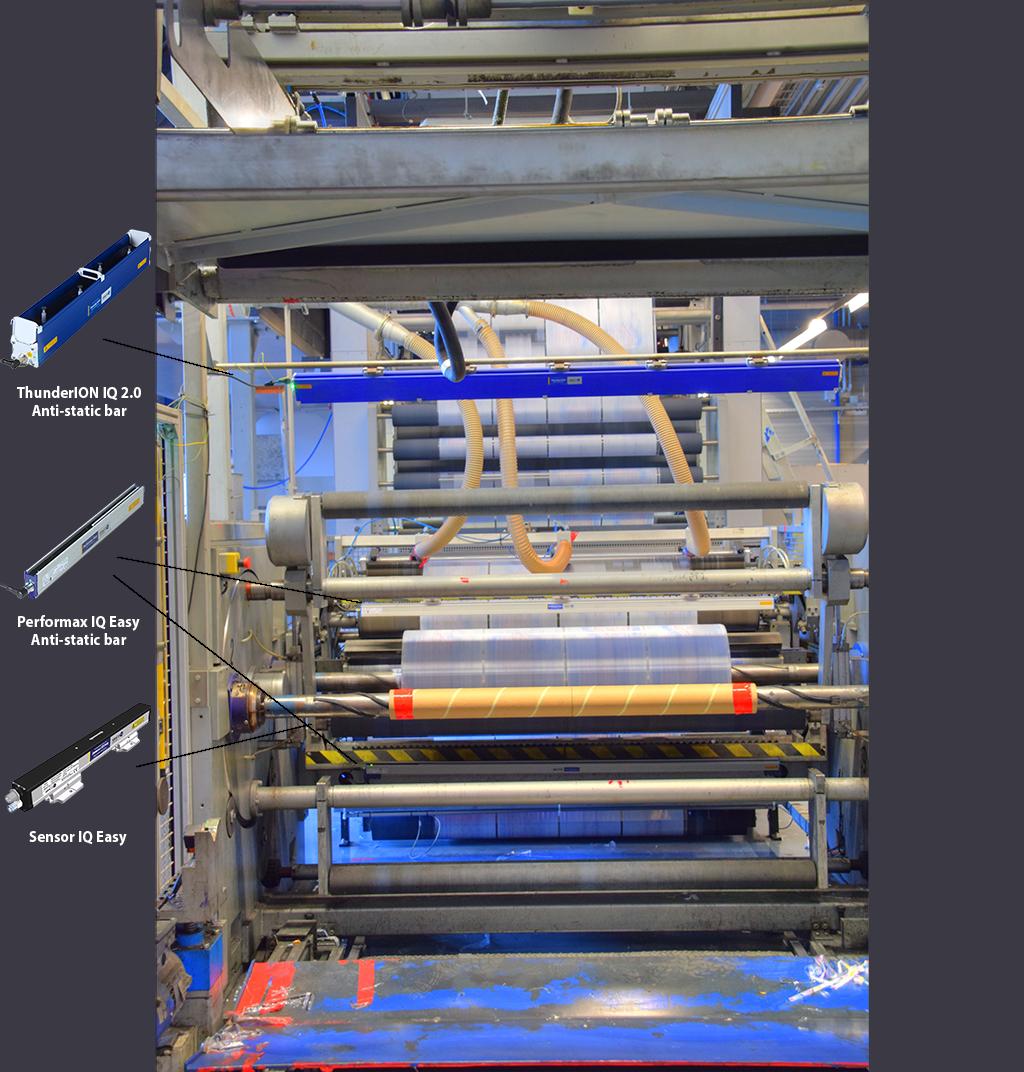

The static charge on the final roll is now reduced to a very low level. This is achieved by placing 2 Simco-Ion Performax IQ Easy anti-static bars together with a Sensor IQ Easy, close to the winding unit.

The Sensor IQ Easy is equipped with three sensors, continuously measuring the static charge at 3 positions across the full width of the foil. This information is shared with the two Performax IQ Easy anti-static bars through the Manager IQ Easy – the central processing unit within the system. The Performax IQ Easy anti-static bars can then adjust their performance continuously based on the measured values in order to achieve the lowest possible remaining static charge on the roll.

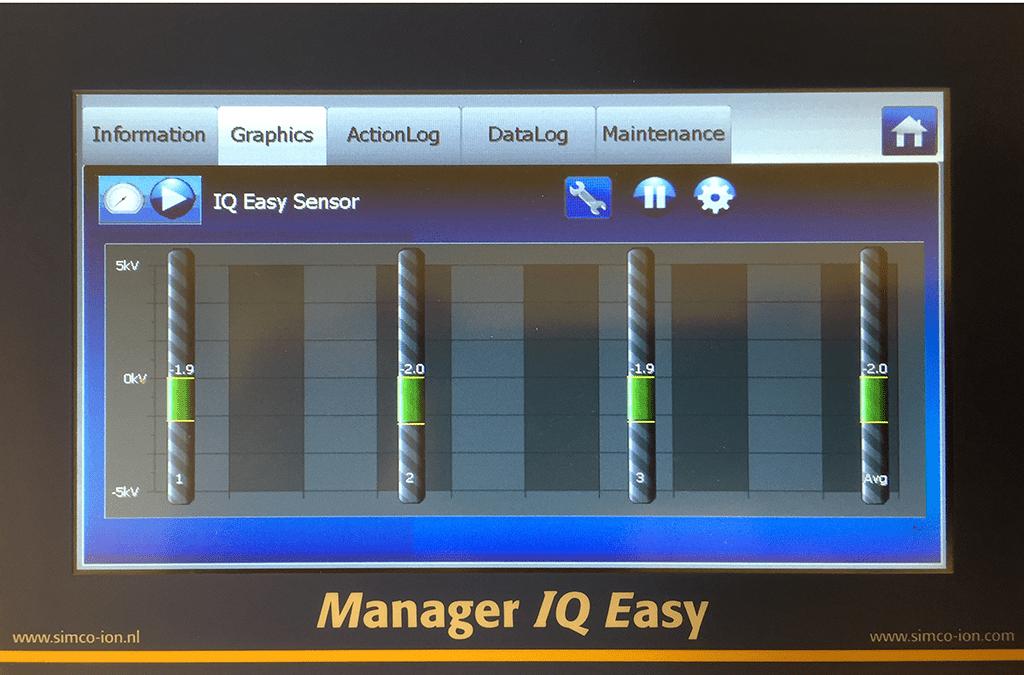

The measured values are displayed on the Manager IQ Easy LCD colour display and stored in the internal memory. Saving this data offers an additional advantage: The manual measurement of the static charge on the finished roll and the subsequent manual recording of these values in a log is no longer necessary.

Wil de Lange, KAM manager at Clondalkin:

“Thanks to our structural approach and optimisation of the production area and process, we are now very satisfied with the achieved results. The Simco-Ion IQ Easy system has contributed a big part to this, we now get a consistently good result and customer complaints are prevented.”

“Ultimately it reduces costs and improves quality, since manual measurements of the static electricity are now made obsolete and compensation due to complaints are avoided. Also maintenance of the ionisation equipment can be better planned, thanks to the indication of fouling and monitoring the trend of the static charge measured by the Sensor IQ Easy. This prevents unnecessary machine downtime.”

Just as with Clondalkin, Simco-Ion’s goal is an optimal collaboration with its customers. The worldwide active representatives strive to improve the production process of the customer by implementing equipment for controlling static charges.

The desired result has of course top priority. This is achieved through sound advice and the best and latest equipment. 24 Volt technology and a 4-year guarantee ensure a reliable, sustainable and consistent result.

Curious how Simco-Ion can also improve your production process involving static charge?

We would be glad to learn about your needs and schedule a nonbinding consultation.

18. octubre 2016

Very good application!